Weekly/monthly (prophylactic) maintenance work

• clean gas appliances;

• lubricate movable parts (slides, guiding frame of floating drum plants, taps etc.);

• servicing of biogas-driven engines within the prescribed time intervals;

• maintenance of pressure relief valves and under pressure valves;

• maintenance of slurry agitator / mixer;

• control gas appliances and fittings on tightness and function

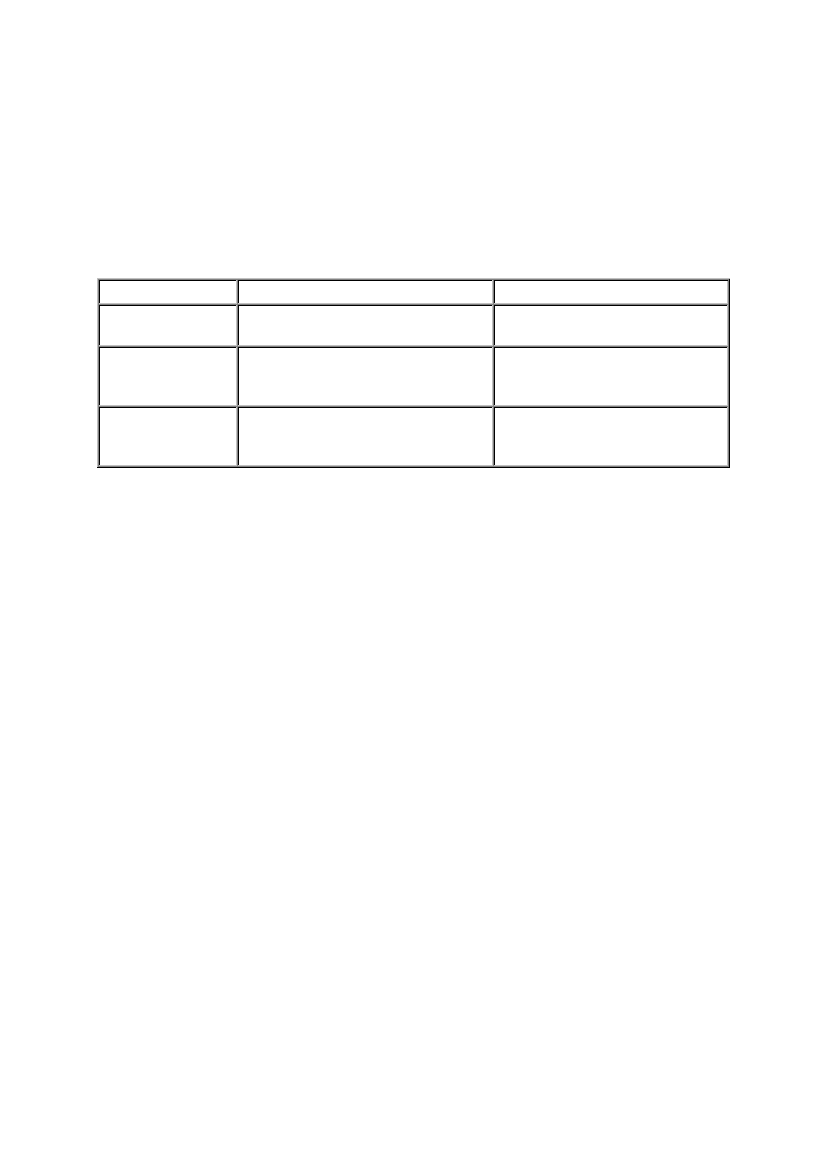

Control of functions

Control

Mistakes

water separator

non-automatic water separator is

full;

piping system

no water is collected in the water

separator; gradient of the pipes is

wrong;

pressure relief and

under pressure non-functioning

valves

Removal

empty the water separator;

Reinstall pipes in a way that

condensation flow leads to the

water separator;

clean valves or renew them

Annual maintenance work

• Check the plant in respect of corrosion and, if necessary, renew protective coating

material;

• Check the gas pipes for gas tightness (pressure check). If necessary, search the

leakage and repair the parts concerned. Note: minor gas leakage is usually

undetected during normal operation as it is ’compensated’ by gas production

Monitoring

Monitoring subsumes all activities of data collection regarding an individual biogas unit or

biogas programs. Collecting data on the performance of biogas units is necessary to

• detect problems in the unit’s performance;

• to have a base for economic evaluation;

• to have a base for comparing different models and different modes of operation

Measurements and other data which become necessary for the optimization of the existing

biogas unit should be recorded by the owner or by a person appointed by him/her. The

records should include the following data:

• The amount and type of substrate, incl. the amounts of mixing water.

• The substrate temperature, if necessary at various stages of the substrate flow

(heated plants). By measuring the substrate temperature, faults in the heating system

can be detected.

• Gas production: measurements are carried out with a gas meter between the digester

and the gas-holder (gas production) or between the gas-holder and the points of

consumption (gas consumption). In simple plants, the gas production can be

estimated during times of no consumption. Changes in gas production and the speed

by which these changes occur give valuable hints on the nature of the problem.

• Electricity and heat production from co-generation units;

• pH-value (monthly); recorded substrate intake;

• content of hydrogen sulfide in the gas (monthly);

• analysis of the fertilizing value of biogas slurry (annually or seasonally) to determine

the optimal amount of slurry to be spread on the fields.

73